A wide range of burnishing tools, both by using hardened rollers or diamond tips, to achieved by turning a polished surface with a height reduction of roughness.

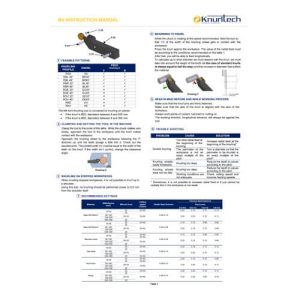

Introduction of burnishing

Burnishing is a machining technique in which a tool is pressed on the surface of a part of lower hardness, crushing the microscopic ridges generated in machining by chip removal and thus reducing its roughness.

This crushing of the ridges displaces the material from the ridges to the valleys and evens out the unevenness. The result of this operation is the generation of a polished surface, with a significantly lower surface roughness.

Details/Data Download