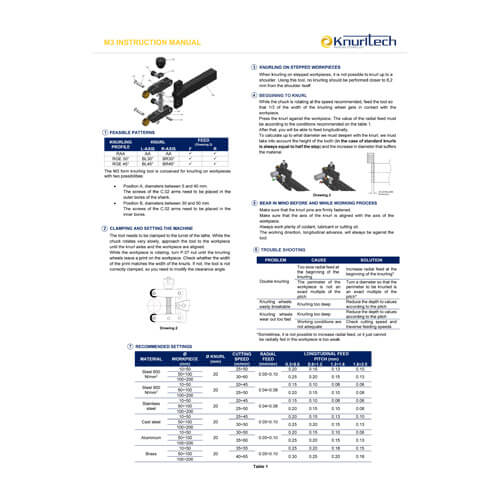

Clamping And Setting The Machine

The tool needs to be clamped to the turret of the lathe. While the chuck rotates very slowly, approach the tool to the workpiece until the knurl axles and the workpiece are aligned.

While the workpiece is rotating, turn P.07 nut until the knurling wheels leave a print on the workpiece. Check whether the width of the print matches the width of the knurls. If not, the tool is not correctly clamped, so you need to modify the clearance angle.