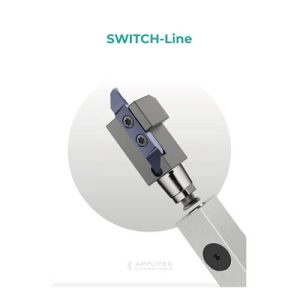

Infos and advantages

Rigid !

- Applitec clamping system with shifted teeth

- Standard clamping system (A)

- Clamping system type B*

-

The insert can be changed in the machine without removing the toolholder

Space requirement

Designed to maximize efficiency in the tightest spaces

Optimal clamping

The recommended tightening torque is 2 Nm